Back to top

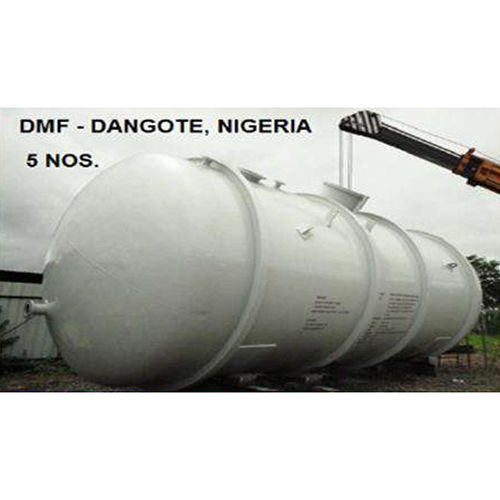

We are the prime choice of clients to avail premium quality Air Receivers, Vertical Filter Vessels, Refinery Storage Tanks, and more.

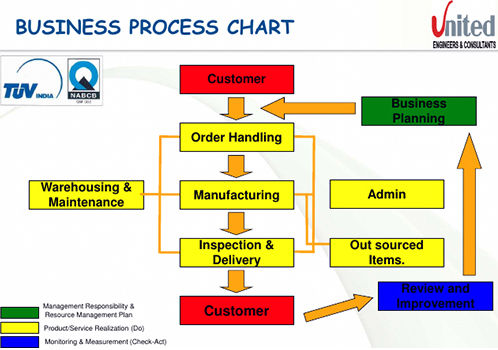

Company History and Its Operations

Mission and Vision: Quality and Environmental Policy

At United Engineers & Consultants, we strongly believe that by establishing a well-structured quality and environmental management system, we will be able to achieve our goal of being counted among the most reputable and top manufacturers, exporters, and service providers in the market. However, we aim to:

Engineering Facility and Set-Up

At United Engineers & Consultants, we are dedicated to offering the best products to our patrons. In an attempt to achieve our aim, we have set up a robust engineering facility to help us with a flawless production process. Our engineering facility is equipped with technologically advanced machinery, equipment, and tools. Each piece of equipment is fluent in performance and has the ability to enhance productivity. Similarly, we make use of a variety of software tools to streamline our operations. Some of the software tools that we make use of are as follows:

Manufacturing Area and Facilities

Similar to how we have developed an engineering facility, we have constructed a state-of-the-art manufacturing unit. Outfitted with cutting-edge machines and managed by a team of certified production experts, the unit extensively supports us throughout the production of our range of Refinery Storage Tanks, Vertical Filter Vessels, Air Receivers, and other products. Mentioned below are certain specifications describing our manufacturing area:

Our Certifications

For providing remarkable services and a top-notch product range, we, United Engineers & Consultants, have achieved several laurels. Today, a wide audience recognizes us as top providers of a superior-quality yet cost-effective range of industrial products. In our journey, we have achieved various certifications; some of which are mentioned below, highlighting our business excellence:

- As we, United Engineers & Consultants, are in the 21st century, we proudly state that all our business operations are conducted using the latest technological advancements.

- Since the beginning, we have been striving to serve a wide customer base with perfectly executed services such as the designing, engineering, and manufacturing of Heat Exchangers, Process

- Equipment, Pressure Vessels, Process Columns, Oil and Gas & Water treatment industries, Skid Mounted units for Fertilizer, and others. All the services are curated as per the needs of the customers.

- Entered the business in the year 2006 with the aim of competing globally. However, with hard work and perseverance, we have achieved it and have become one of the most reliable manufacturers, suppliers, service providers, and exporters.

- Due to our strong commitment to complete customer satisfaction, we have grown exponentially, garnering a large pool of customers. We ensure to fulfill all the requirements and demands of our customers on time and in the most perfect manner. However, with our unwavering dedication to delighting our customers, we have risen to prominence and are well-recognized as reliable and top providers of Air Receivers, Refinery Storage Tanks, Vertical Filter Vessels, and other products in the industry.

- Apart from the aforementioned, we have diligently followed an open communication policy to ensure employee safety and the highest standards of quality across the products from day one. The employees are motivated to discuss and resolve their issues, if any, to ensure maximum productivity and flawless functioning of the organization.

- Furthermore, through the smooth production of the aforementioned products, we have led the industry all these years. Due to a streamlined management style, well-structured policies, and a simple organized structure, we have been able to deliver an impeccable product range, reflecting a high degree of perfection and profound craftsmanship. Currently, our production capacity is approximately 100150 tonnes per month, with zero accidents reported.

- As a result, today we are the most preferred choice in the market, and we are an ISO 01:2015 certificate holder.

Mission and Vision: Quality and Environmental Policy

At United Engineers & Consultants, we strongly believe that by establishing a well-structured quality and environmental management system, we will be able to achieve our goal of being counted among the most reputable and top manufacturers, exporters, and service providers in the market. However, we aim to:

- Fulfill the requirements of our esteemed customers within the scheduled time frame.

- Train our personnel and enhance our business operations, incorporating innovation at various stages.

- Regularly increase awareness regarding quality assurance across the entire organization, customers, and suppliers.

- Encourage ethical practices for proper waste management and consumption of power.

Engineering Facility and Set-Up

At United Engineers & Consultants, we are dedicated to offering the best products to our patrons. In an attempt to achieve our aim, we have set up a robust engineering facility to help us with a flawless production process. Our engineering facility is equipped with technologically advanced machinery, equipment, and tools. Each piece of equipment is fluent in performance and has the ability to enhance productivity. Similarly, we make use of a variety of software tools to streamline our operations. Some of the software tools that we make use of are as follows:

|

Caesar II |

Ansys |

|

STAAD. Pro |

Solid Edge |

|

Autodesk Advance Steel |

Autodesk Robot |

|

PV Elite |

Intergraph |

|

Transheat Technologies |

Solidworks |

|

HTRI |

Autodesk Revit Structures |

|

Aspen Tech |

Navisworks |

|

CodeWare |

Autodesk Auto CAD Plant 3D |

Some equipment that we use are as follows:

Shell & Tube Heat Exchangers

Piping Stress Analysis

Pressure Vessels, Columns, Reactors, Storage Tanks

Shell & Tube Heat Exchangers

- Thermal and mechanical design of all TEMA-type units.

- Re-rating the performance validation of existing units

- Fixed tube sheet, floating head, and U-tube units.

- Completely detailed engineering and fabrication drawings

- FEA of thin and thick expansion joints

- Vibration analysis of tube bundles

- Design of stub-in-bundles, steam coils in tanks, heating coils in sulfur pits, etc.

- FES for local nozzle loads

- FEA/fatigue analysis for the complete unit based on service conditions

Piping Stress Analysis

- Hot oil supply and return piping systems.

- Piping routing modifications and support selection to ensure that loads on equipment nozzles are within allowable limits

- Static and dynamic stress analysis Tank farm piping systems and process equipment piping

- Turbine inlet and outlet piping analysis

- NEMA analysis for steam turbine piping

- Generation of piping plants and isometric drawings.

- Specification for hanger supports.

Pressure Vessels, Columns, Reactors, Storage Tanks

- Rating of existing units or new service conditions.

- Completely detailed engineering and fabrication drawings

- Complete mechanical design as per ASME Sec. VIII, Div. 1, Div. 2, and PD5500

Manufacturing Area and Facilities

Similar to how we have developed an engineering facility, we have constructed a state-of-the-art manufacturing unit. Outfitted with cutting-edge machines and managed by a team of certified production experts, the unit extensively supports us throughout the production of our range of Refinery Storage Tanks, Vertical Filter Vessels, Air Receivers, and other products. Mentioned below are certain specifications describing our manufacturing area:

- Covered Area: 22000 sq. ft. x 12.5 meters. Ht. with a 20 MT. O/H. crane

- 10000 Sq. Ft.: Blasting and Painting Area

- Radial Drilling Machine: up to 80 mm

- 40000 Sq. Ft.: Utilising raw material and finished goods movement

- Welding rotatorsup to 80 MT Capacity: 10 sets.

- Hydraulic bending machine: up to 40 mm thick.

- Mobile Crane Facility: 12 Tonne

- Shop floors with overhead crane facilities

- Welding: MIG and TIG welding machines with the latest technology

- DFT Metre: for measuring dry film thickness after painting

- NDT Testing: RT and ultrasonic tests are carried out locally with an

- approved facility. DP tests are carried out in-house.

- D Metre: for measuring thickness after dish pressing.

- Hydraulic Testing: Motorised Hydraulic Pump Set Up to 500 Kg/cm2.

- Vernier Callipers.

- Tube Expanding and Growing Machine with Digital Torque

- Measuring Tape: 5 to 30 meters.

- Hydraulic Tube Bending Machine: up to 73 OD x 10 mm thick.

- Cutting: Profile Cutting and Pug Cutting Equipment, up to 100mm Thick

Our Certifications

For providing remarkable services and a top-notch product range, we, United Engineers & Consultants, have achieved several laurels. Today, a wide audience recognizes us as top providers of a superior-quality yet cost-effective range of industrial products. In our journey, we have achieved various certifications; some of which are mentioned below, highlighting our business excellence:

- ISO 9001:2015 under TUV Nord

- CE

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese